Content

Lead-free SMD Soldering Machine

❙ Introduce of Reflow Soldering Oven

Lead-free reflow oven, reflow soldering oven, smt reflow oven, L10 is I.C.T mature product after years of market testing.E Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various welding processes, It is I.C.T crystallization of years technical research and development. E Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products .

1. Control System

Computer or Instrument control, make sure machine working steadily.

2. Hot Air Heating System

Both top and bottom zones hot air heating,good heater compensatory,High thermal efficiency,energy saving,speedy heating,suitable for soldering components like BGA,CSP etc.Special forced hot air circulation structure makes PCB and components heat evenly, Temperature Accuracy ± 1.5 °C, room temperature settling time less than 20 minutes.

3. Cooling System

Independent cooling area ensures the low temperature when PCB comes out.

4. Transmission system

Use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min.

❙ Specification of Reflow Soldering Oven

| Model | E8 | E10 |

| Dimension (L*W*H)mm | 5000x1250x1490 | 5800x1250x1490 |

| Weight | Approx. 1600KG | Approx. 1800KG |

| Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

| Length Of Heating Zones | 3121mm | 3891mm |

| Rail Width Adjustment | M(option:A) | |

| Exhaust Volume | 10M3/minx2 Exhausts | |

| Control System | PLC+Computer | |

| Temperature Control Method | PID + SSR | |

| Transmission Agent | Chain + Mesh | |

| Electric Supply Required | 3 phase,380V 50/60Hz | |

| Power For Warm Up | 55KW | 64KW |

| Power Consumption | 8KW | 12KW |

| Warming Time | Approx.25 minute | |

| Temp. Setting Range | Room Temp.-- 300°C | |

| Conveyor Height | 900+/-20mm | |

| Conveyor Speed Range | 300~2000mm/mi | |

| Fixed Rail Side | Front Fixed (Option:Rear Fixed) | |

| Cooling Method | Forced-Air Motor and fan (Standard) | |

❙ I.C.T Customer Factory

▽ Russia customer - Full SMT production line

▽ Poland customer (Battery Chargers and Adapters) - Full SMT production line

▽ Customized reflow soldering oven for HUAWEI Shenzhen, Qingdao, Dongguan, Wuhan factory.

▽ I.C.T full-auto LED TV production line with reflow oven and DIP line in Ecuador

❙ Company Profile

Successful Experience:

I.C.T Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

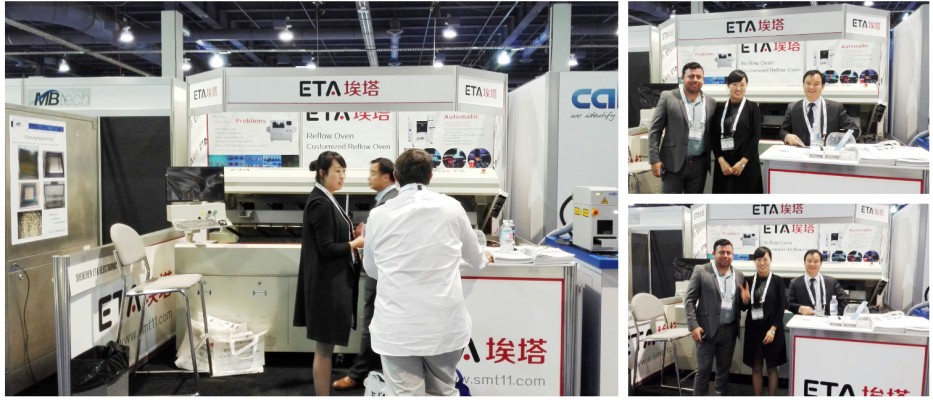

❙ I.C.T SMT Machine Exhibition

❙ Reflow Soldering Oven Certificate

❙ I.C.T Global Service

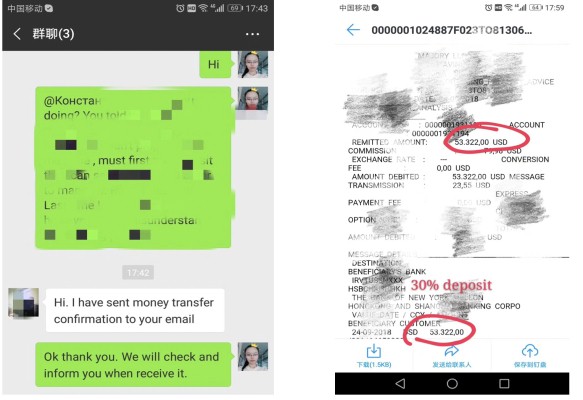

❙ Customers' Feedback

❙ FAQ

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.

❙ PCB Reflow Oven Video